1. Introduction of Moresuperhard GC-X3 Dressing Machine

This machine tool uses the principle of the speed difference between the dressed grinding wheel and the dressing grinding wheel to achieve the shape dressing of the dressed grinding wheel.

The machine itself can provide simple and efficient dressing for diamond grinding wheels, CBN grinding wheels and grinding wheel groups composed of multiple grinding wheels. It can dress planes, angles, arcs and profiled grinding wheels. This machine is easy to operate and has high precision. It has the following features:

1. It uses precision linear guides and ball screws, and adds a digital grating ruler (optional) so that the positioning accuracy, width size and arc size of the grinding wheel can be adjusted and measured at any time when it is being dressed.

2. The rotating A-axis uses high-precision tapered roller bearings to meet the requirements of rotation accuracy and rigidity.

3. The speed, left and right swing speed, swing stroke and the position of the center of swing of the dressing grinding wheel are all adjusted.

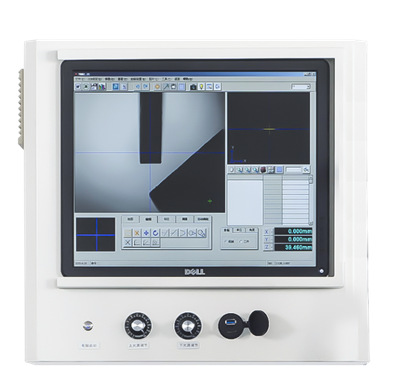

4. Equipped with a video measurement system with a magnification of 15 to 100 times and a 19" LCD monitor, it can measure and inspect the arc, angle and size of the grinding wheel online during work.

5. The CCD and optical size device provide easy-to-use settings and measurement of the width and position of the grinding wheel as well as inspection during or after dressing. The measurement accuracy can reach 0.005∽0.01mm.

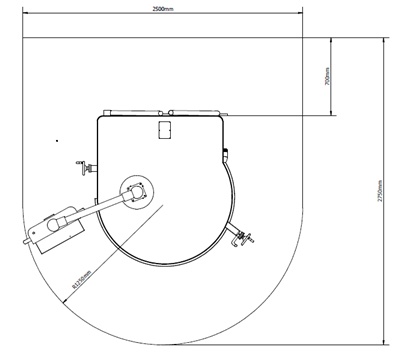

2. Main technical parameters of Moresuperhard GC-X3 Dressing Machine

1. X and Y axis magnetic scale resolution 0.001mm

2. The diamond grinding wheel (to be dressed) spindle is equipped with a BT40 inner taper hole 80mm spindle as standard

Other grinding wheel connecting rod interface spindles are optional

3. Maximum diameter of diamond grinding wheel Ø250 mm

4. Minimum diameter of diamond grinding wheel Ø50 mm

5. Maximum thickness of diamond grinding wheel 50 mm

6. Diamond grinding wheel spindle speed 100~1500rpm variable frequency speed regulation

7. Diamond grinding wheel left and right stroke (X) 120 mm

8. Diamond grinding wheel front and back stroke (Y) 120 mm

9. The diamond grinding wheel arc can be dressed R0.1~10 mm

If it exceeds this range, the lens needs to be replaced

10. Recommended size of dressing wheel (SIC) Ø180*10*Ø31.75 mm

11. Dressing wheel spindle speed 500~2500rpm variable frequency speed regulation

12. Dressing wheel left and right swing frequency 0~50/min (adjustable)

13. Left and right swing distance of dressing grinding wheel 0~45/mm (adjustable)

14. Total power of machine tool is about 2.0kW

15. Silicon carbide grinding wheel motor 0.75kW

16. Dressed diamond grinding wheel motor 0.75kW

17. Reciprocating swing motor 0.025kW

②: Move diamond spindle assembly, which can be increased to 400mm.

②: If the radius of the arc to be trimmed is greater than 10mm, the lens needs to be replaced.

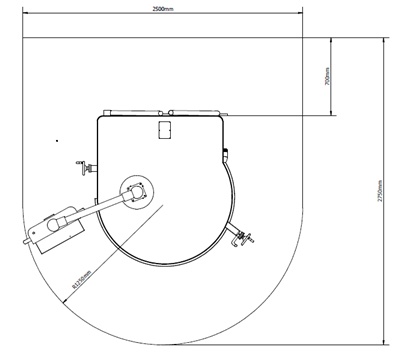

3 Transportation and installation of Moresuperhard GC-X3 Dressing Machine

3.1 Handling equipment

·Optional forklift or hydraulic lift: Minimum load: 3.0 tons

Minimum fork length: 1200mm

3.2 Assembly of the machine

The machine is mounted on 4 vibration-damping supports on the machine.

With these supports, the machine is precisely leveled in both longitudinal and transverse directions.

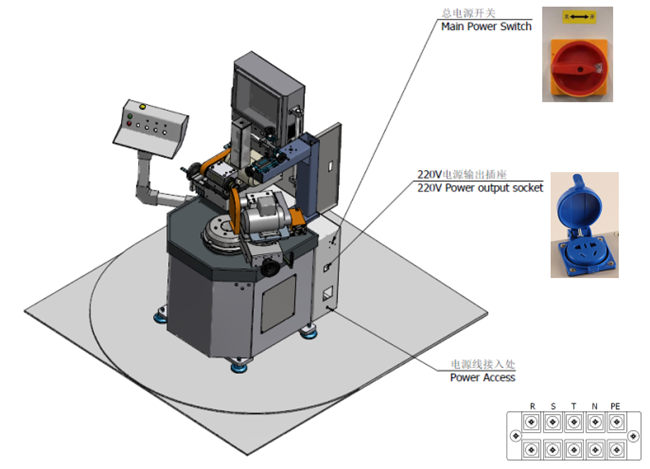

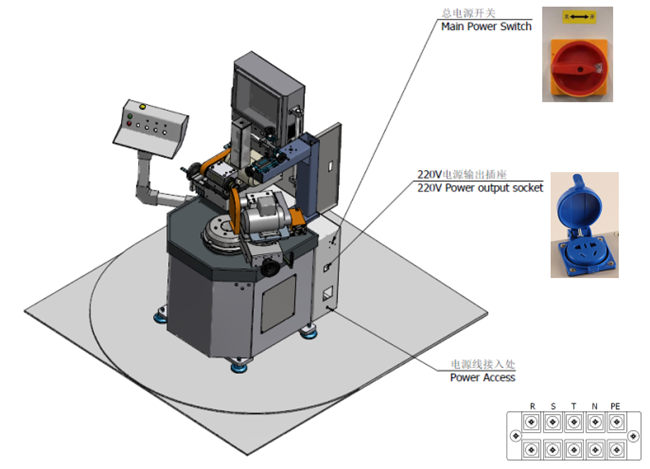

3.3 Power connection

The whole system is connected to the local mains through the input terminal of the power supply

All further electrical connections are made between the plug and the terminal between the electric control box and the machine

Connection value:

Electrical connection:

Mains 3*380V/50Hz

Connected power 5.0kVA (including vacuum cleaner power supply).

The minimum input fuse is 16A

4. Operation of Moresuperhard GC-X3 Dressing Machine

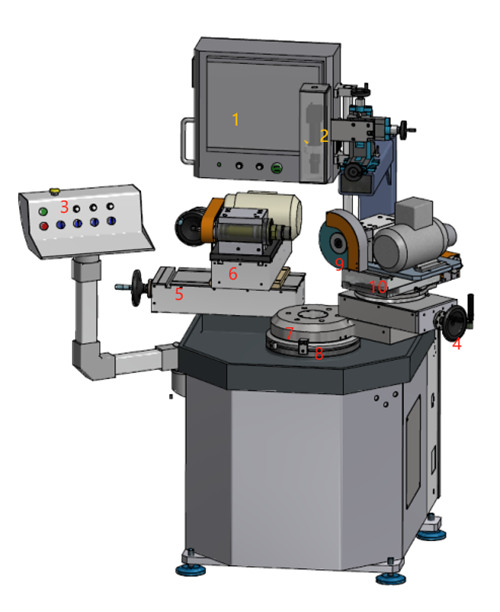

4.1 Machine function diagram and operation instructions

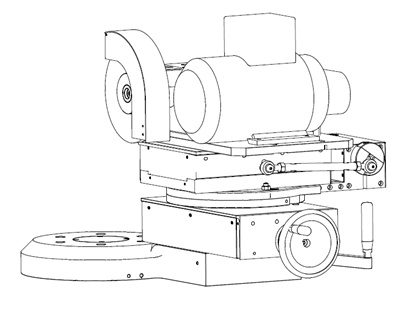

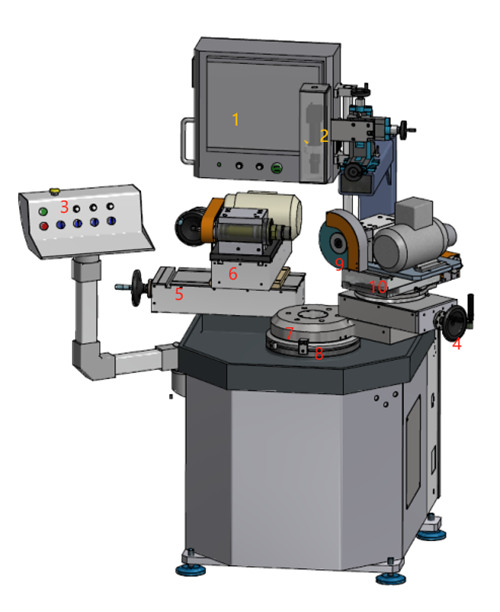

4.1.1 Machine function diagram:

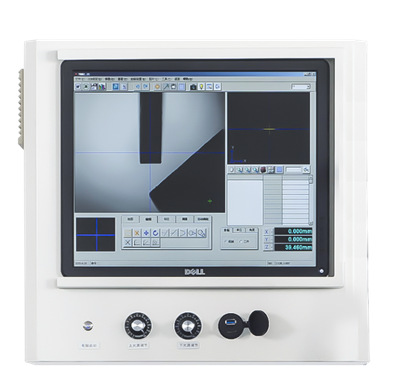

4.1.2 Machine operation panel:

1. Power off 2. Starting power 3. 4.5. Speed Control

6. Emergency stop switch 7. Video switch 8.Dressed grinding wheel 9. SIC grinding wheel 10.sway

4.1.3 Video Detection System Panel:

1. computer 2. Upper light source 3. Lower light source 4. USB interface

4.1.3 Start using the machine:

* Turn on the main power switch

* Release the emergency stop button

* Press the power button

* Set the speed to 30%, about 500rpm. , Turn on the diamond wheel spindle motor switch

* Set the speed to 50%, about 1000rpm. , Turn on the silicon carbide wheel spindle motor switch

* Set the speed to 50%, about 25hz. , Turn on the swing switch,

Then, adjust the appropriate speed according to the parameters recommended by the diamond wheel supplier.

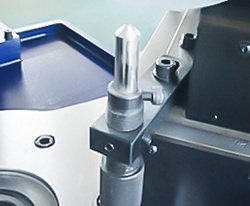

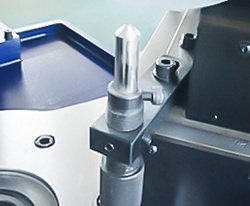

4.1.4 Installing and dressing silicon carbide grinding wheel

1. Grinding wheel safety cover

2. Silicon carbide grinding wheel flange

3. Silicon carbide grinding wheel

4. Diamond dresser point

4.1.4.2 First dressing of Sic grinding wheel

1. Install the diamond pen holder and lock the screw

2.Height adjustment locking screw

3.Rotate the tool holder and adjust the height of the diamond dressing point to contact the Sic grinding wheel

4.Turn on the silicon carbide grinding wheel motor, turn on the swing motor, adjust the appropriate speed, and start dressing the silicon carbide grinding wheel.

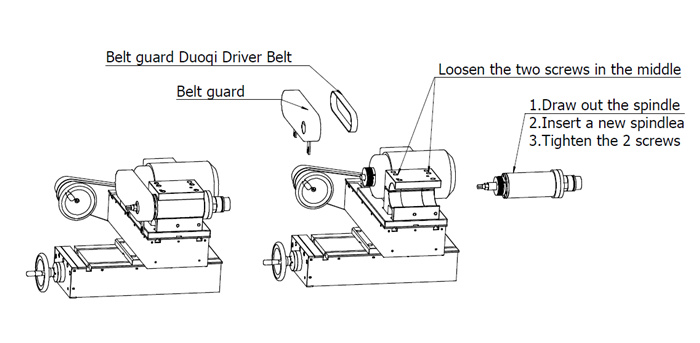

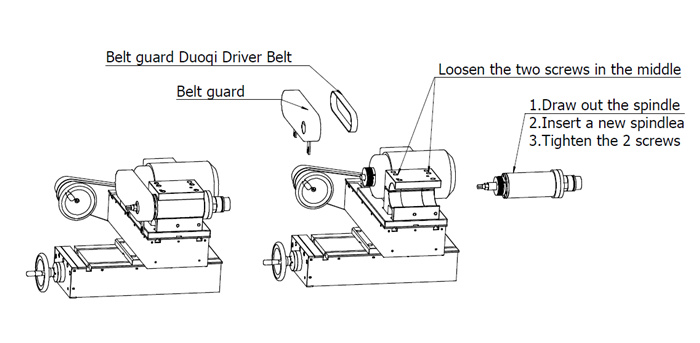

4.1.5 Replacing the diamond grinding wheel spindle

4.1.6 Installing and removing the diamond wheel group

- Use an Allen key or wrench

- Loosen the nut with a socket wrench

- Carefully move the HSK grinding wheel

4.1.7 Adjustment of grinding wheel swing distance and swing center

1. Loosen the hexagonal screw

2. Turn the middle sleeve to adjust the swing center of the Sic grinding wheel.

3. Loosen the screw with the hexagonal key

4. Use the hexagonal key to adjust the screw here to adjust the swing stroke

5. Tighten all the screws and bolts to complete the adjustment

4.1.8 Start dressing the diamond grinding wheel:

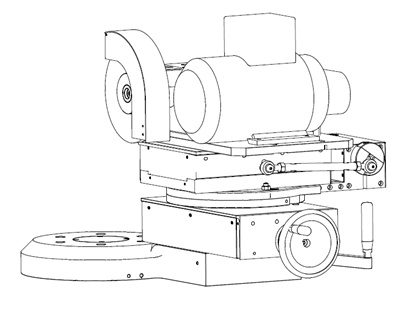

After completing the above two tasks, rotate the rotating seat to 0 degrees (Figure 7) and ensure that the swing part is at 90 degrees (Figure 8).

- Adjust the speed of the silicon carbide grinding wheel motor; ② Adjust the reciprocating motor to the appropriate swing frequency; ③ Adjust the diamond grinding wheel motor to the appropriate speed; ④ Use the hand wheel to control the Sic grinding wheel close to the diamond grinding wheel and start dressing.

4.1.9 Adjust the center of the rotating arc

4.1.9.1 Adjust the projection

Place the calibration glass and bracket in the center of the lower light source, adjust the appropriate lens magnification, observe the small square on the calibration glass, and adjust the hand wheel on the top of the lens bracket until the small square is most clearly displayed on the screen

4.1.10 Handwheel focus adjustment

- Draw a circle with a radius of 3 mm by editing, and manually input the circle

- Rotate the turntable to 0 degrees, move the feed handwheel, so that the Sic grinding wheel projection fits under the circle, and when the turntable rotates to 90 degrees, observe the silicon carbide grinding wheel projection fits the circle. If there is a deviation, adjust the knob and feed handwheel of the microlens holder, and the adjustment distance of the knob and handwheel is half of the total distance, so that the projection is tangent to the circle.

- Turn the left side of the turntable to 90 degrees and the right side to 90 degrees. Repeatedly adjust the knobs of the lens holder and the Sic grinding wheel feed handwheel to make the projection tangent to the circle.

- Adjust the turntable to 0 degrees again, and turn the lens holder y-axis knob to make the projection tangent to the circle

4.2 Dressing diamond grinding wheel

4.2.1 Plane grinding wheel

5. Install diamond grinding wheel, adjust X/Y hand wheel to make diamond grinding wheel in the middle position on the computer screen, lock X/Y hand wheel to rotate the turntable to 0 degrees, lock the turntable, adjust the hand wheel to make the circumference of silicon carbide grinding wheel close to diamond grinding wheel, adjust the reciprocating travel of green silicon carbide grinding wheel to ensure that green silicon carbide grinding wheel can go out of both sides of diamond grinding wheel on the left and right, and start green silicon carbide grinding wheel silicon grinding wheel, diamond grinding wheel, silicon carbide grinding wheel reciprocating motion, hand wheel feed to start grinding.

4.2.2 Grinding angle grinding wheel

Adjust the rotating panel to the required angle, lock the turntable, adjust the reciprocating stroke, start Sic grinding wheel, diamond grinding wheel, Sic grinding wheel swing motion, hand wheel feed to start grinding.

1. Turntable angle limit

2. Turntable

3. Turntable locking

4. Angle indicator

5. Feed slide

4.2.3 Dressing the arc grinding wheel

① Adjust the rotation center according to the instructions

② In the software, use the method of editing the manual input circle to draw the circle to be cut, and move the position of the diamond wheel so that the circle corresponds to the position to be cut.

③ Set the turntable limit block, and the angle on both sides must not exceed the cutting position.

④ Adjust the reciprocating stroke.

⑤ Start the diamond grinding wheel motor/Sic grinding wheel motor/swing motor, feed the handwheel to make the Sic grinding wheel contact the diamond grinding wheel, and manually control the turntable handle to rotate back and forth to start dressing

5.Instructions for use of main accessories of Moresuperhard GC-X3 Dressing Machine

5.1 Video microscope: Optical magnification 0.7x 4.5 continuously variable, with 0.5x eyepiece.

5.2 Display: 17-inch LCD.

5.3 Bearings use precision-grade bearings, and guide rails use precision cross-roller guide rails.

5.4 Feed handwheel resolution is 0.02 mm

5.5 Swinging motion is driven by a DC gearbox motor, and a turbine gearbox can also be selected.

5.6 Airflow atomizer

6. Troubleshooting Guide

6.1 VMM2.2 Software Startup Problem

Please check the help file to start this software.

6.1.1 Check if the camera power indicator (red light) is on.

6.1.2 Check if the AV plug on the top of the camera is damaged.

6.1.3 Start the VMM software, click "CCD set (D) - Video gather Card - DirectShow (USB 2870 or UCAP2820)" - click "OK".

6.1.4 Click "CCD setting (D) - Display properties - Video" decoder - Video standard (PLA_G) - click OK.

6.1.5 Restart the VMM2.2 software

7. Operational safety instructions of Moresuperhard GC-X3 Dressing Machine

1. After adjusting the position of the diamond wheel to be trimmed, lock the x-axis and y-axis handwheels.

2. Before trimming the grinding wheel angle, the turntable must be zeroed and the computer angle display must be set to zero. The computer angle display is the correct angle.

3. Before starting the straight line trimming work, the turntable must be locked.

8. Description of machine components of Moresuperhard GC-X3 Dressing Machine

1. LCD and video system control panel

2. Camera

3. Control switch panel

4. Turntable rotation handle

5. X-axis platform

6. Y-axis platform

7. A-axis turntable

8. Turntable locking device

9. Silicon carbide grinding wheel feed handwheel X1

10. Silicon carbide swing slide Y2

.jpg)